Closed-Center Hydraulic System

Due to the extremely high demand, all kits are now sold out for Spring 2024 delivery.

Please contact us for Fall Pre-orders to guarantee your kit.

For High-Demand Applications

Our Closed-Center, Load-Sensing systems match the capacity delivered by the pump to the load requirements. This allows for an increased range of flow without the headaches of overheating issues. Providing an additional 40 gpm at 3,000 psi when operating at 2,100 engine rpm, we ensure you won’t be left short when you need power! A system more adaptable to changes in demand allows producers the versatility to run more than just an air cart. Modern implements such as sprayers, grain carts, planters, and active shank drills all present special challenges due to varying flow rates. By sensing these changes, our systems can provide an accurate amount of flow for each application, resulting in you tractor and implement running at peak efficiency!

For ultimate convenience, the rate of flow can be adjusted from the cab using our electric joystick control assembly. This allows you to make adjustments on the fly, without costly downtime. All Closed-Center systems are custom built based on your applications specific needs, giving you the confidence that your tractor will remain profitable now, and into the future.

How We Do It…

Tractor Models Available

| Make | Models |

|---|---|

| Versatile | 750, 800, 825, 835, 850, 855, 875, 895, 945, 955, 975 |

| Ford/Versatile Designation 6 | 936, 946, 956, 976 (with 855 Cummins Engine only) |

| Case STX (2001-11 models) |

375, 380, 425, 430, 450, 480, 500, 530 |

| Case Steiger | 380, 385, 430, 435, 480, 485, 530, 535 |

| New Holland (2001-11 models) |

TJ 375, TJ 380, TJ 425, TJ 430, TJ 450, TJ 480, TJ 500, TJ 530, T9030, T9040, T9050, T9060 |

Optional Upgrades

| Option | Upgrade |

|---|---|

| Quick Couplers | 3/4″ standard; 1/2″ optional |

| Heat Exchanger | Radiator Mounted or Electric Fan Blown |

Hydraulic Kits are available only for listed models.

System Specifications

| Spec | Options |

|---|---|

| Type | Closed-Center, Load-Sensing |

| Hydraulic Flow | 40 gallons per minute at 2,100 engine rpm |

| Maximum Pressure | 3,000 Pound Per Square Inch |

| Control Valving | Proportional Spool |

| Control Type | 12 VDC Proportional Joystick |

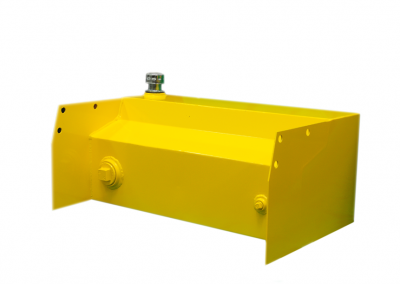

| Hydraulic Reservoir | Versatile Tractors: Add-On 30 Gallon Capacity; All Others: Existing Reservoir |

Atom‑Jet Hydraulic Kits are manufactured by the experts at our Glendale Industries facility, 1520 Charles Street, Brandon, MB.