Points of Difference

Seed/Fertilizer Placement

Great seed to soil contact leads to quicker germination for a superior plant stand – it’s what all growers want.

our vertically designed opener has the ability to place the seed on a firm seedbed immediately after opening the soil, eliminating seed bounce and soil fracturing.

Due to a sleeker profile, closure is achieved in a very short amount of travel, creating an impeccable field finish.

Openers of horizontal design attempt to drive seed against the direction of travel, usually resulting in seed bounce and poor overall placement.

Atom-Jet agriculture pioneered the vertical design.

It’s true innovation that competitors in our market continue to emulate to this day.

Soil Disturbance

The shape and form of our vertical design isn’t simply the most stylish profile available, it’s practical too.

• By causing the soil to be split, we nearly eliminate the throw that comes with bulkier horizontal openers reducing your risk of not retaining enough soil to cover the seed or cause stepping.

Trash Clearance

Our vertical installation and smooth body is a huge asset when it comes to trash clearance.

Trash rides up the point and clears around the vertical rounded seed tube.

Same Plane Placement

All Atom-Jet openers utilize “Same Plane” placement during the delivery of seed and fertilizer to the seedbed.

Atom-Jet Agriculture was the first to implement, “Same Plane” placement to prevent the seedbed from fracturing.

• Atom-Jet believes a fractured seedbed dries out quicker and generates the potential for uneven germination.

• It also increases the risk of seed burn by creating an area where seed and fertilizer can merge.

A firm seedbed produces good seed-to soil contact, enabling enhanced absorption of moisture and nutrients by the seed, while excluding fertilizer from the seed row.

No-Plug Technology

Through vertical design, mud blockage and plugging have been virtually eliminated.

• The curved area under the point or “mud spur” is made to inhibit soil from “orange peeling”

• Competitors’ horizontal designs actually precipitate the mud curl travelling up and into the rear of the opener.

Our vertical design produces a larger seed gallery, ensuring the seed drops freely onto the seedbed, minimizing internal plugging.

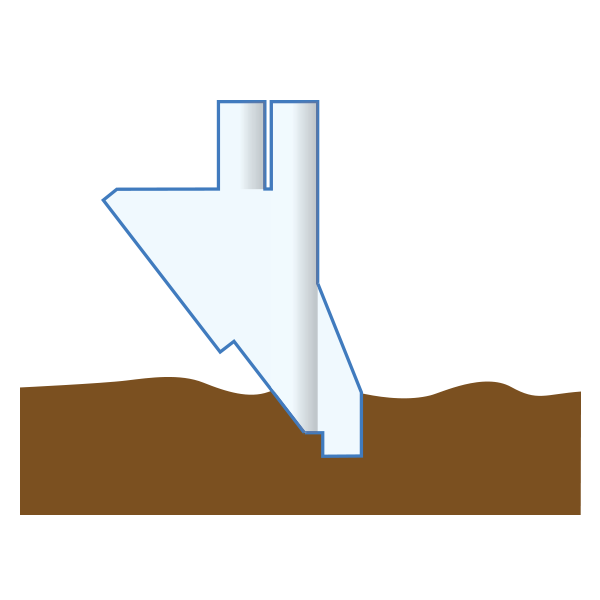

Soil Penetration

Vertical design simply uses the weight of your drill to penetrate the ground at the smallest point on your opener-—the tip.

With horizontal openers, you are attempting to puncture hardpan with the widest part of the tool.

Draft

With the cost of fuel increasing, reducing draft is of the utmost importance.

With Atom-Jet you won’t be forced to seed deeper to place the seed where it needs to be, increasing the load on your tractor and implement.

Our streamlined design keeps you moving economically across the field.

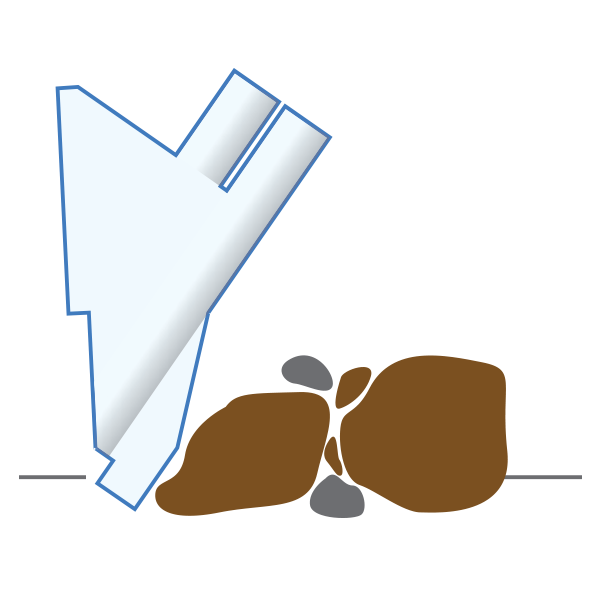

Rocks

As “C”-Shanks trip, the opener actually goes deeper into the ground before coming up and out.

• This action turns horizontal designs into some of the best rock picking tools available, placing huge amounts of stress on drill frames and shanks.

By developing our openers to have a flatter design at the point, it produces a shape that is more likely to float across the top of the stone, rather than hook or pull it up into your field.

Maintainable

Atom-Jet openers are formed from quality steel plate and fortified with high-grade hard surfacing.

• This presents producers with the ability to extend the life of their purchase through the replacement of points, wings and tops.

All hard surfacing can be renewed to its original condition.

• If you can weld, hard surfacing can be done yourself or send the opener to us and we will recondition it for you.

Carbides

For over 20 years we have delivered the ultimate in carbide technology to producers around the globe.

With continued research into grade, shape and installation techniques, we continue our never ending quest to innovate better tools.

Compare us to the competition and see for yourself why Atom-Jet is the driving force in carbide technology.

Chute Size

The vertical design allows for a large open gallery right behind the point, minimizing plugging.

• In comparison to our competitors, Atom-Jet has the advantage of the largest seed gallery.

Double shoot openers that direct seed to the side have a large seed chute.

• This allows for seeding of broader seeds such as peas and beans.

• The large chute allows the seed to easily get around the bend, reducing the risk of plugging.

Concerns With Lower Point Openers

Fractures the soil allowing the escape of moisture content.

Risk of uneven germination.

Potential for seed to mix in with fertilizer as the seed rolls down the shoulder of the furrow.

Increased soil throw.